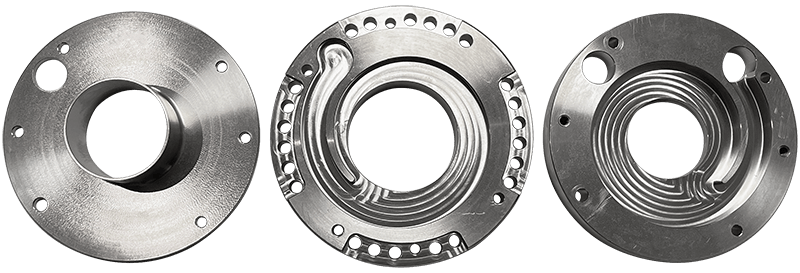

The BästDry Tech brand media distribution disk adopts a reduced volute distribution disk. Through CFD flow field simulation experiment, the liquid entering the atomization disk can be evenly distributed. At the same time, the volute flow channel is designed with a self-cleaning structure, which provides more anti clogging and anti scaling capabilities of the media distribution disk.

The medium distribution panel is made of AISI Gr3, which has higher corrosion resistance.

Media Allocation Disk Parameters

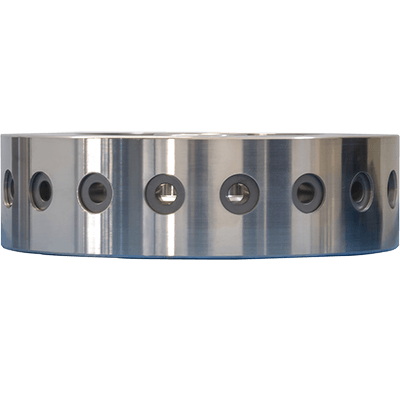

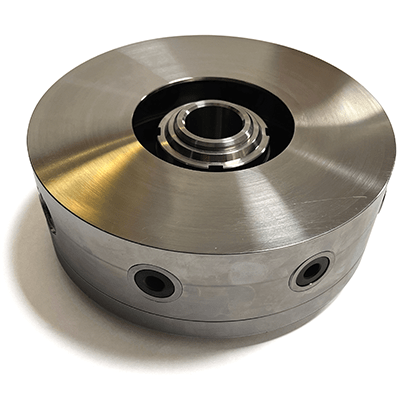

The BästDry Tech brand rotary atomizing disk adopts a 4 – 12 channel design to make the diameter of the rotary atomized droplets more uniform, and the diameter of the rotary atomized droplets can reach 10-50 µm.

The BästDry Tech brand rotary atomizing disc is made of Hastelloy C276 material, and silicon carbide material is embedded in the area with high flow rate according to CFD flow field simulation, so that the service life of the rotary atomizing disc can reach more than 8 000 h.

The internal flow channel of BästDry Tech brand rotary atomizing disk adopts self-cleaning structure design, which makes the anti scaling and anti blocking ability of rotary atomizing disk more excellent, and extends the cleaning cycle of rotary atomizing disk.

Head Quarter Sweden

Adress

BästDry Tech AB

Anderstorpsvägen 11

SE-332 36 Gislaved, SWEDEN

Telephone

+46 116 13 03