According to different production needs, BästDry Tech brand rotary atomizers are divided into DG series and FC series products. DG series products are recommended to be used in the spray drying absorption process and high temperature evaporation process of concentrated solution in the field of environmental protection, while FC series products are recommended to be used in the drying of new energy materials, fine chemical products, and food/drug products.

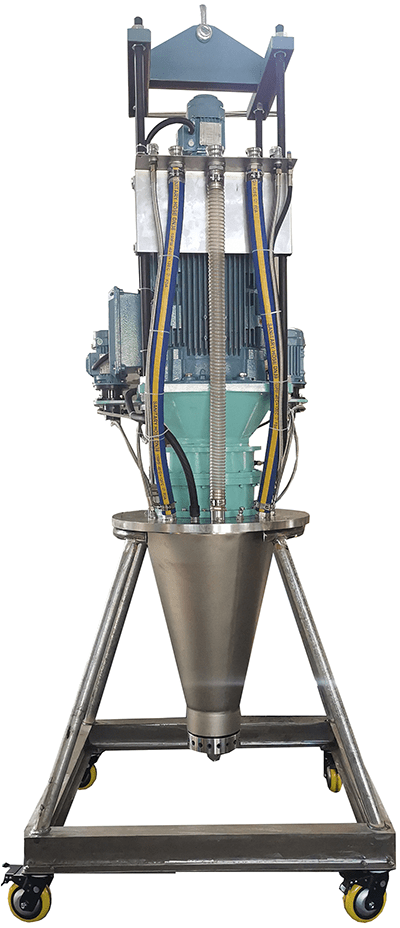

DG Series

DG series products are mainly used for garbage incineration, biomass fuel incineration, industrial waste gas fuel incineration, sulfur dioxide removal of metallurgical industry tail gas and high-temperature drying of highly concentrated liquid. The rotating speed of DG series rotary atomizer is 12 000-16 500 rpm, the maximum linear speed of rotary atomizer is 181 m/s, the atomized particle size is 20–50 um, and the maximum processing capacity is 50 000 kg/h.

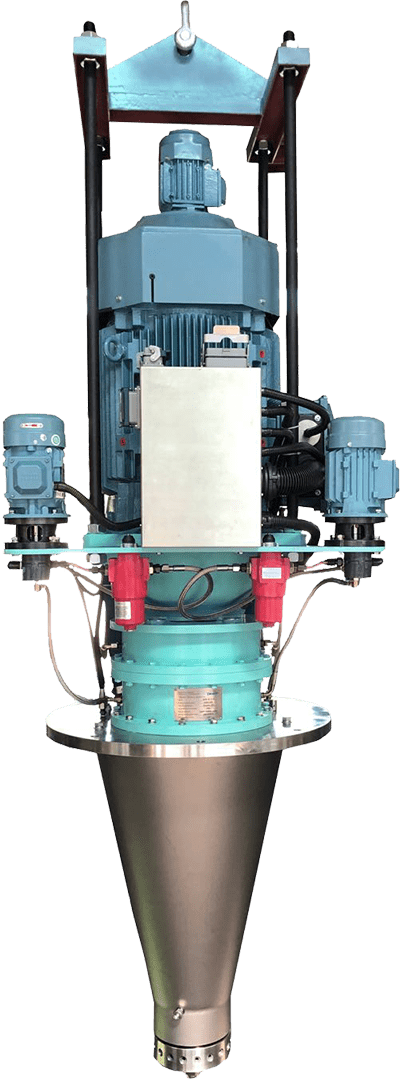

FC Series

13 500 – 23 000 rpm, the maximum linear speed of rotary atomizer is 259 m/s, the atomized particle size is 10-30 um, and the maximum processing capacity is 15 000 kg/h.

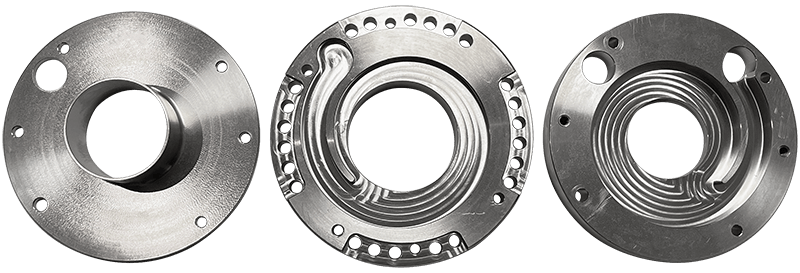

Media Allocation Disk

The BästDry Tech brand media distribution disk adopts a reduced volute distribution disk. Through CFD flow field simulation experiment, the liquid entering the atomization disk can be evenly distributed. At the same time, the volute flow channel is designed with a self-cleaning structure, which provides more anti logging and anti scaling capabilities of the media distribution disk.

The medium distribution panel is made of AISI Gr3, which has higher corrosion resistance.

Power Distribution and Control System

BästDry Tech brand rotary atomizer provides a complete set of power distribution and control cabinet, in which VVVF and control system are designed. We can also equip PLC control system according to customer needs.

We are equipped with professional cables for rotary atomizers with industrial con-nectors, which can greatly shorten the repair and maintenance time of rotary atomizers through the application of industrial connectors.

Design capability and technical services

BästDry Tech can provide complete overall services for different production needs of customers. BästDry Tech can provide the following design services:

- Design of the whole spray drying and absorbation process (SDA)

- Design of spray drying of the whole concentrate

- Design of hot air distributor

- Calculation of material balance

- CFD flow field simulation of the whole process

Head Quarter Sweden

Adress

BästDry Tech AB

Anderstorpsvägen 11

SE-332 36 Gislaved, SWEDEN

Telephone

+46 116 13 03